Hot Spray Marking Machine (HS)

details

Hot Spray Marking Machine (HS)

PREVIOUSNEXT

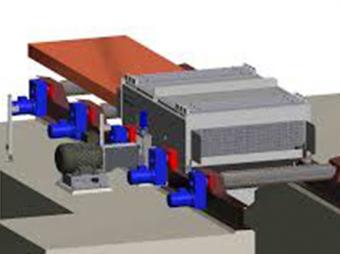

The Hot Spray Marking Machine is designed for the marking of slabs and blooms, even in the harsh environment of steel plants. Marking is performed by blowing liquid metal which is melt in an electric arc between two wires to the surface of the product.

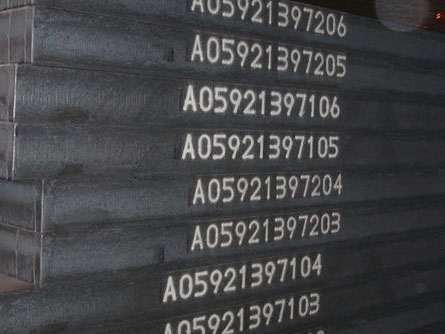

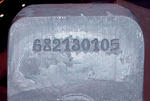

Hot Spray Marking Machines are distinguished especially by marking of long-lasting characters, which can vary in size and number of lines depending on individual customer requirements. The complete equipment is manufactured using standardised modules, which result in high reliability and low maintenance of equipment and specially selected electrical and mechanical parts that are designed, well tested and proven to function in heavy industries.

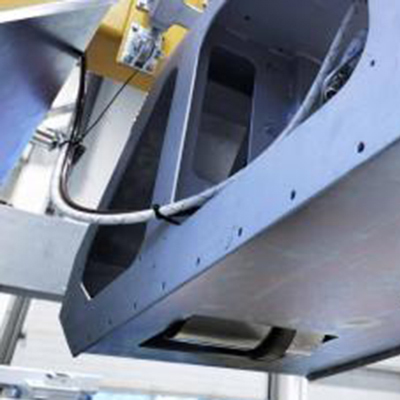

The Hot Spray machine frame consists of a robust fabricated construction with linear rails and safety devices for the marking head. The characters are generated by an electrical writing movement of the marking head with x and y axis driven by servo motors. The machine is controlled by a PLC type Siemens S7 with standard interfaces to steel plant equipment and fault diagnostic system.

Temperature range from 20 to 1,100 °C

Alphanumeric and special characters, size from 60 to 150 mm

Marking media: Aluminium, bronze or filling wire

Your advantages:

- Low operating costs due to use of standard aluminium welding wires up to 900 °C

- Low consumables costs, only electrical and pneumatic media supply is necessary

- Large characters offer a high visibility even from the crane operator

- Durability of marking at least a half year at outdoor storage

- Simplicity of system allows an easy maintenance

Products other

NUMTEC Shroud Manipulator (SM)

Contact

NUMTEC deburrer slab

Contact